All posts by Giulio

Spring 2014

NET ZERO STADIUM – Castro Mello Arquitetos

Brazil’s showcase eco-arena expected to be a centrepiece of global attention

By GREG McMILLAN

Watch Copa Verde movies:

https://www.yousendit.com/download/UVJpYnU5NEgzeUlYRHRVag

http://copaverde.com/copaverde/ThePlan__Home.html

By the time the 2016 Olympic Games are underway in Brazil, the world will know all about a ground-breaking showcase eco-arena located in the heart of the nation’s capital, Brasília.

Brazil’s national stadium, or Estadio Nacional de Brasília, will get more than its share of global attention long before 2016 – as it will be the centerpiece for soccer’s 2014 World Cup.

Designed by Castro Mello Arquitetos of San Paolo, with Ian McKee, LEED AP, serving as green building and sustainability manager for the project, the stadium is aiming for LEED Platinum designation. Work is continuing leading up to the World Cup in June 2014.

“We were given the tremendous opportunity of building a stadium for the World Cup,” McKee says. “This was a moment for our firm, this was a moment for our country, to build the best stadium in the world.”

With a seating capacity of 68,009, the stadium will have a number of environmentally-conscious features.

Right off the top, 90 per cent of the materials from the original demolished stadium are being recycled or reused onsite. There is a rainwater harvesting and reuse system, water-saving plumbing fixtures, a two-megawatt solar photovoltaic (PV) system and LED lighting.

Of special note: Potable water consumption will be reduced by more than 80 per cent. And a breathable façade will provide sufficient ventilation in the seating bowl and main concourses.

“The large white roof protects the building and the area around the bowl and the inner bowl,” McKee explains. “The roofing reduces the heat island effect. And the solar power integrated into that roof improves overall energy efficiency.”

The site will feature habitat restoration with native plantings and improvements to pedestrian access. The stadium’s location in the center of Brasília allows for bike valet parking for 3,500 bikes inside and around the facility—unprecedented bike parking capacity for a stadium. Because more than 50% of emissions related to stadium operations are related to fan transport to and from the event, the design team felt it was critical to provide alternative, emissions-free transportation options.

“When we tell people they will be able to ride their bikes right into the stadium and drop them off with a bike valet, you can see it in their eyes … that this is going to be a new stadium experience,” says McKee.

The project is expected to be the first net-zero energy stadium in the world and a net energy producer. While the solar PV system is estimated to produce 2.8 million kilowatt-hours (kWh) annually, the project is only expected to use approximately two million kWh per year. As a result, the remaining energy produced will be passed on to Brasília.

Outside the stadium, the design team has hoped to draw attention to an area geared to “pleasurable, healthy” experiences. More than 6,000 native plant species will be planted, ideally creating a rich and diverse park open for all to enjoy. Walkways will be permeable for water absorption into the soil and lightly colored to further reduce the heat island effect.

Additionally, swales will capture and direct stormwater runoff from parking areas, cleaning the water and removing chemicals and solids. The deposits will be placed in a man-made lake for possible reuse inside the stadium.

These strategies, aided by recycling and composting initiatives, will allow stadium visitors to learn about sustainable living, landscaping, engineering, as well as green design and building, McKee says.

“The stadium is really designed for the local environment, fully focused on sustainability,” he adds. “And it’s an effort to have Brazil recognized as a model for the world to follow.”

Pushing the geothermal envelope

Innovative GeoSmart Energy earns solid reputation for expertise and knowledge

By GREG McMILLAN

There’s an adage used by sports teams that goes something like this: You’re only as good as the players around you.

In many ways, that same maxim applies to the business world. And a specific example can be found with GeoSmart Energy, one of the largest non-manufacturing based distributors of geothermal heating and cooling solutions.

How does the GeoSmart team push the envelope? They make sure their geothermal specialists and their customers have access to the most effective and efficient geothermal energy products and services available on the market today.

“GeoSmart Energy is a brand of geothermal heat pumps,” says Chad Brezynskie, Vice-President, Sales & Marketing, GeoSmart Energy. “We are a privately-owned Canadian company with a grassroots team that has come from the trenches. And we have an amazing group of contractors on our team.”

Brezynskie tells Green Building and Sustainable Strategies magazine that the contractors, in fact, allow GeoSmart to pull away from the field.

“They are the ones that do all the hard work. They take our product to market and we appreciate every opportunity they give us to work with them on a project.”

GeoSmart, Brezynskie says, separates itself from competitors by only working with a select group of contractors, then supporting them from design to project completion. And that could also involve collaborations with architects, engineers and building owners.

“It’s not just geothermal, it’s high-performance geothermal,” he says. “Just about anyone can make it work, but that shouldn’t be the measure of success.

“We follow up in a year or two. Is the customer happy? Are they as comfortable as they thought they would be? We believe the measure for success is whether the system is performing as planned, or better. It’s about achieving performance and comfort. Doing that comes with experience and we have a lot of that.”

Besides having a full line of residential and high performance commercial product available, GeoSmart also prides itself on ingenuity.

“We have the right products for virtually any project,” says Brezynskie, “but when it comes to the heart of the system – the outside loop – we have been quite innovative.”

One example is how GeoSmart decided to create a unique identity for geothermal ground loops about 10 years ago.

“Gas pipe is yellow, sometimes orange, and almost everything else is black,” he says. “That’s what most of our competitors use – black. But not us, we created green geothermal pipe. That’s what colour it should be. If someone is digging and they hit a green pipe, now they know what it is.”

But GeoSmart didn’t stop there.

“We looked at the material the pipe was made of, as well, and improved on that. The industry always used PE3608. It’s a pretty good resin, very good at handling pressure and temperature change and transfers heat fairly well.

“But our green geothermal pipe uses PE100. It has all the same properties [high density polyethylene] of the previous generations of resin, but with dramatically higher strength. This means we can use a thinner wall, and still have a higher pressure rating, all the while achieving better heat transfer.

“So all of our pipe is green and is made of PE100. It’s the best.”

The cost and energy-efficiency of geothermal is also a big selling point, he says. “We can reduce a building’s cooling cost by 50 per cent and that can be a huge saving in a large office building. And heating costs for a rural home using propane or oil can be reduced by up to 75% with geothermal. It’s huge.”

The GeoSmart team sees a lot of different construction methods and architecturally-challenging projects, however Brezynskie says any uniqueness is never especially daunting.

“We can always integrate into the environment seamlessly,” he says. “That’s the thing about selling comfort, it just needs to be there … all around you. You can’t see it or hear it, it’s just there.”

Web: http://www.geosmartenergy.com/

ARQUIETECTONICA

More than computers

Microsoft headquartered in standout sustainable building in Paris, France

The Microsoft brand has always been synonymous with change and innovation – and that link often goes far beyond the world of computer technology.

Case in point: Microsoft France is headquartered at Paris’ EOS Generali building, which has garnered earned substantial environmental certifications.

The building, located in the city’s Issy-les-Moulineaux area, achieved both BREEAM (Building Research Establishment Environmental Assessment Methodology) In-Use and HQE (High Environmental Quality in Use) Exploitation® standards.

The project, jointly initiated by the owner, Generali Real Estate, and the main lessee, Microsoft France, is a first in western European country; improving overall environmental performances.

The building, designed by international architectural firm Arquitectonica, has improved the environmental performances of the site and have been able to generate energy savings of more than 25 per cent.

The certifications testify to the excellent quality of the ecological and sustainable management and operation of the real estate complex.

Arquitectonica is an architecture, interior design and planning firm that began in Miami in 1977 as an experimental studio. Led by Bernardo Fort-Brescia and Laurinda Spear, the studio has evolved into a worldwide practice, combining the creative spirit of the principals with the efficiency of delivery and reliability of a major architectural firm.

Today, Arquitectonica has a practice across the United States directed from regional offices in Miami, New York and Los Angeles. Arquitectonica’s international practice is supported by a European regional office in Paris; Asian regional offices in Hong Kong, Shanghai and Manila; the Middle East regional office in Dubai; and Latin American regional offices in Lima, Peru, and São Paulo, Brazil.

The organization focuses on ecologically-sensitive, yet commercially-viable, design, and is widely recognized for its ability to create unique forms of memorable imagery in close harmony with the environment. The firm explores the complex challenges of contemporary built and natural environments, developing solutions that balance a modern aesthetic with an ecologically sensitive practice to create value, identity and a sustainable environment.

Since its founding in 1977, Arquitectonica has won numerous American Institute of Architects and Progressive Architecture Design Awards.

Web: arquitectonica.com

Technical Achievements

Eos Generali, Issy les Moulineaux, France

HEQ High Environmental Quality – High Efficiency Level

The High Environmental Quality (HEQ) label is a sustainable-development approach applied to the design, construction and operation of buildings, with a view to controlling their impact on the outside environment and ensuring that the interior atmosphere is healthy and comfortable. Ratings are in three levels, “highly efficient,” “efficient” and “HEQ validation”

Compliance is recognized by official certification awarded by the construction-sector scientific and technical French centre (CSTB) in respect of new service sector buildings that comply with specifications including 14 points. It also reflects the Generali Group’s desire to invest in sustained development.

“Highly Efficient” Level in following categories

Eco-construction harmonious relationship between the building and its immediate environment

Eco-management water management

Eco-management management of upkeep and maintenance

Comfort Visual comfort

“Efficient” Level in following categories

Eco-management energy management

Comfort olfactory comfort

Health quality of air

Health quality of the water

The High Environmental Quality (HEQ) label also means lower energy consumption, which in turn, means lower cost for the tenant.

Air Conditioning

Radiant panel air conditioning with 1.35 m addressable zones

Ceilings

Metal ceilings with clear height of 2.8 m in the offices

Air

Low pressure fresh air system

Canvas Blinds

Adjustable canvas sun blinds

Raised Floors

Raised floor with 12 cm clear height

Power Supply

Power supply with 4 standard power points per work station

Awards

AIA Florida, Award of Honor for Unbuilt Work, 2006

Eco-Building Forum, ““Grand Prix” award, top prize for achievements in sustainable design”, 2007

Society of American Registered Architects (SARA), Design Award of Merit, 2010

AIA Miami, Honor Award of Excellence in Architecture, 2013

HUMBER RIVER HOSPITAL

The future of healthcare: lean, green and digital

Humber River Hospital, designed by HDR

In 2008 the Ministry of Health and Long Term Care (MOHLTC) approved funding for Humber River Hospital (HRH), to begin the planning and design of a 167,300 sm (1.8 million sft) acute care facility on a dense urban site in the middle of Toronto’s North York region. The objective was to combine on one site the services and patient care currently being delivered at three different sites. With this goal in mind Infrastructure Ontario (IO) and HRH partnered to achieve the largest hospital in Ontario and second largest in Canada.

As a major capital project IO and HRH began the process of procurement through the Public, Private, Partnership (PPP) delivery model. HRH envisioned creating a hospital founded upon a “New Model of Care”; while remaining firmly rooted in the diverse community the Hospital serves. For HRH it was important that the new facility’s design not compromise the health of building occupants, the surrounding community and natural resources.

Humber River Hospital, designed by HDR

Humber River Hospital, designed by HDR

HOK Architects Corporation (HOK) was entrusted with realising HRH’s vision as the Planning, Design and Compliance (PDC) Architects. HOK is an industry leader in both Healthcare and Sustainable design; bringing to the project leadership in planning and systems development, and a focus on developing a holistic sustainable vision for the overall site. HOK led HRH’s staff and physicians through a comprehensive planning process to develop the specifications, and create a test design establishing innovations and strategic direction for the new Facility; characterized by Lean, Green and Digital principles. Although these principles address different aspects of the hospital’s operations and development they are intertwined; enabling the hospital to provide best quality service to the community while being a thoughtful local neighbour, supportive employer and responsible health and wellness citizen.

The new site is located on the former parking lot of a government services campus; with residential neighbourhoods to the north and major arterial expressway to the south. The planning team met the challenge of providing within a 26 acre site a 167,300 sm (1.8 million sft) new home for a broad range of health care services; while creating efficient, ready access for patients and staff. HRH 656 bed Facility anticipates receiving 136,000 ER visits, 5,300 births, 192,700 ambulatory visits and 40,700 surgeries each year. To accommodate such large volumes of visits to HRH’s services within the site’s size confines HOK proposed to leverage cutting edge technologies and planning concepts.

Humber River Hospital, designed by HDR

Humber River Hospital, designed by HDR

Business cases for automated supply delivery systems utilizing robots, complex pneumatic transport of soiled laundry and linen to external haulage units, and the use of a pneumatic tube delivery network are just some of the features implemented to achieve efficient healthcare operations. As a result of these initiatives Barb Collins, HRH’s Chief Operating Officer, believes that the hospital is “on track to save 164 kilometres per day of walking time, with a potential savings of $2,000,000 per year in operating costs.”

Another key strategy is the HOK-developed “Portals of Care”. Similar to an airport drop off this concept allows visitors to access HRH’s services effectively and intuitively at specific drop off points; channeling traffic flow according to desired destination. Compared to a traditional hospital the separation of access to different types of services (like ER, dialysis, ambulatory and inpatients) enhances accessibility for the community, boosts efficiency and gives HRH the ability to manage pandemic incidences without shutting down all services. The cumulative result of HOK’s strategic approach to planning and internal supply delivery is the optimum use of site conditions to achieve a large, complex, state of the art hospital on a tight urban site.

Some of the most advantageous impact HOK’s contribution has had on the realization of the hospital are the sustainable strategies focused on Facility energy consumption. Recognizing that a healthy environment is intrinsically linked with wellbeing, HOK and HRH set forth to minimize the new hospital’s energy footprint and reduce its yearly operational costs. Hospitals are one of the most challenging building types; with “24-7-365” activity, strict indoor environment requirements and occupant safety demands that result in power intensive systems and equipment.

With this in mind the HOK team designed hospital systems with focus on the implementation of energy recovery measures, leading-edge systems design and efficient operational protocols; using typical industry means and methods. At the same time the goal was to maintain 100% fresh air delivery to all areas of the hospital, optimizing indoor air quality.

An integrated design group (including HRH, HOK, The Mitchell Partnership and Mulvey & Banani International Inc.) set a target of 40% energy cost reduction from the base case in ASHRAE 90.1 2007. Nine months of research (using energy modeling, test design inputs, cost verifications and a concerted focus on enhancing conventional systems to reduce energy use) proved that 40% energy cost reduction could be achieved for this building type and size. Despite doubt from the Proponent Consortiums, HRH and HOK were confident in the research and that their vision could be attained.

To ensure that the sustainable innovations and targets were met once the project was released to the bidders, HOK specified in the bid documents that 15 points were to be achieved for the LEED® Canada-NC 2009 Credit EA – Credit 1: Optimize Energy Performance. Sample test design and energy model data equating to 40% energy cost reduction was included to guide the bidders. In addition the consultant team specified essential requirements based on the research test design; examples being the delivery of reduced air velocities and the utilization of waste heat, while leaving enough opportunity for market and industry value assessments. To ensure success HOK worked with IO to implement the Energy Guarantee Letter; an aspect of the Project Agreement between HRH and the winning Project Company Consortium that stipulates a specific energy usage in the 30 year Facilities Management contract. Where the LEED Credit EA – Credit 1 targets energy costs, the Energy Guarantee Letter targets actual energy use and is not impacted by the fluctuation of energy prices. In HRH’s case this leads to a 50% reduction of energy use from the base case; ensuring that the hospital will continue to achieve energy reductions once in operation, and into the future.

As the Consortium team continues to build the new facility the vision is beginning to be realized. Once HRH opens in the fall of 2015 it will be considered one of North America’s most energy efficient hospitals. The research developed through HRH’s and HOK’s leadership puts the new hospital on track to provide over $3,000,000 per year in operating expense savings. HRH is on target to achieve LEED gold and the predicted energy use will be 1.15GJ/square metres/year versus the North American average of 3GJ/m2/year. These efficiencies will offset 11,371 tonnes of CO2 per year; equivalent to taking either 2,187 cars off the road, saving 409,356 twenty-five year old maple trees or saving 4,373 acres of forest. In addition the site will be planted with 800 new trees to meet the City of Toronto’s Tier 1 planning specification. The Facility’s Energy Use Intensity is on target to be 103 kBTU/square foot/year; putting HRH 15 years ahead of the 2030 challenge of 101 kBTU/square foot/year.

Humber River Hospital, designed by HDR

Humber River Hospital, designed by HDR

The vision and innovations of HRH, its stakeholders and the consultant team have made possible the reimagining of a hospital’s mandate and the site’s potential. The result is a highly sustainable health hub for the community and City; setting a new standard of care that balances social, financial and environmental wellbeing.

When the classroom becomes the teacher

Eco-friendly portable features ideals of health, sustainability and energy efficiency

It’s probably safe to say that it’s a rare occurrence when parents, students, educators, school administrators, custodians and maintenance personnel are all on the same page.

But that will almost certainly be the case when they begin talking about a new unique portable classroom called a mobEE (mobile eco enclosure), a learning space containing ideals of health, sustainability and energy efficiency.

Commercialized by Evolve Builders Group, the mobEE is a unique portable classroom constructed with an array of techniques spanning from natural and renewable materials to ultra-modern design and high-tech features. In fact, the portable classroom merges super green straw bale building and other natural building techniques with state-of-the-art construction technology.

“Parents and educators will find much to their liking about mobEE; mobEE is a place of learning where the building itself is part of the lesson,” says Ben Polley, founder of Evolve Builders Group. “Moreover, mobEE provides a natural, safe, healthy environment for children’s well-being.

“Administrators, custodians and maintenance personnel will similarly be enthused by mobEE’s benefits,” he continues. “No-wax floors simplify cleaning and maintenance and the durable permanent-quality construction provides exceptional life-cycle cost benefits.

“And given the (Ontario) Green Energy Act’s requirement for all school boards to now publish the energy intensity of each school, mobEE may provide an affordable way to meet provincial efficiency targets.

“Schools may never have another opportunity to meet so many goals with one easy decision.”

Standard mobEE features include:

- Fire resistant straw bale insulation;

- Glass viewing window into wall core;

- Structural insulated panel floor and roof;

- Fibreglass-framed high-efficiency windows;

- Natural, vinyl-free, waxless, antimicrobial linoleum flooring;

- Mineral-based wall paints, in and out;

- LED warm-white light fixtures;

- Wood soffit with natural finish;

- And steel roof with recycled content or low emissivity white roof membrane.

After participating in the design and/or construction of three separate two-classroom permanent schoolhouses built similarly to mobEE, Evolve worked in conjunction with the facility department at the Upper Grand District School Board to craft this highly-functional, affordable, healthy portable.

Polley says this is an example of the type of partnerships where academic researchers and industrial designers frequently seek out Evolve’s experience and participation.

Evolve’s involvement at the pre-commercialization stage with large and trusted institutions is both an acknowledgement of Evolve’s diverse capabilities and helps contribute to its ability to propose the best solution for their clients complex needs, says Polley.

“Few builders are so involved in the making of the industry, not just the making of buildings themselves,” Polley says.

Specializing in green construction and eco-friendly renovations, Evolve Builders Group is a full-service general contractor and homebuilder, registered with Ontario Tarion New Home Warranty.

Web: evolvebuilders.ca

Paving the way for green HVAC

Mits Airconditioning Inc. designs high-end custom heating and air conditioning solutions.

Mits Airconditioning Inc. makes no bones about it – its company raison d’être is to offer top of the line service in its distribution of long-lasting, premium, and environmentally-friendly HVAC products. As a company slogan says: Paving the way for green HVAC.

Founded in 1987 by owner and president Jack Eliav, Mits Airconditioning Inc. (Mits Air) is well-known in the HVAC (Heating, Ventilation and Air Conditioning) industry for its premium brand offerings, superb customer service, inventory of equipment and parts at all times, and on-time deliveries.

The experienced team at Mits Air works closely with clients to design the most suitable, effective and efficient HVAC systems for diverse projects such as hospitals, hotels, nursing homes, schools, residential buildings, educational institutions, commercial buildings, unique historic sites, high-tech computer and server rooms, and LEED certified buildings.

Based in southeastern Ontario, Mits Air holds distribution rights to several high-end product lines including, but not limited to, Mitsubishi Electric MrSlim™, Mitsubishi Electric City Multi, Mitsubishi Electric Zuba Central, Lossnay™, Renewaire, DiamondAir Horizontal and Vertical Water Cooled units, Aermec S.P.A. Chillers and Heat Pumps, IBC Boilers, Laars Boilers, Navien Tankless Water Heaters, Noritz Tankless Water Heaters, Bard Wall Mounted units and Oceanaire Air and Water Cooled Portable units, as well as Vesbo piping and other accessories that complement the product lines.

Eliav has more than 35 years of experience in the heating and air conditioning industry. The company’s head office in Mississauga, Ontario includes a 42,000 square-foot stocked warehouse with equipment and parts for all of its products, as well as a fully operational showroom and training centre. In addition to its head office, Mits Air has an office and warehouse in Barrie, Ontario.

Mits Air takes pride in not only distributing products, but in working with architects, consulting engineers and contractors from concept to completion of each custom project, to ensure that all solutions are both functional and aesthetically pleasing. The company seeks to ensure that its designs and applications are innovative, cost-effective, and environmentally-friendly.

Mits Air also believes in the value of education and spends substantial resources training its customers on the products and brands it distributes. Its 2012 move to a new facility 2.5 times larger than its previous location allowed Mits Air to offer even more frequent and comprehensive training due to its new state of the art, fully-functional showroom and large training facility. Mits Air focuses on developing its training programs so that its customers are updated with new product training, advances in technology, and certifications on the products they purchase and subsequently install, ensuring greater end-user satisfaction.

A forward-looking company that has continued to grow exponentially since its inception, Mits Air was recognized by PROFIT Magazine (PROFITguide.com) in 2013. In the magazine’s 25th annual PROFIT 500 issue, Mits Air was ranked number 360 on the list of Canada’s fastest- growing companies.

With a long history of offering green products that are environmentally sustainable, Mits Air continues to build its green inventory. Through its new alliance with Italian manufacturer, Aermec S.P.A., Mits Air now distributes Aermec’s unique cooling and heating solutions to North America, which add to Mits Air’s core Mitsubishi Electric product line.

Mits Air has distributed Mitsubishi Electric’s high-end products for over 27 years.

In its complete range of commercial and residential HVAC solutions, Mitsubishi Electric has demonstrated a commitment to new technologies, energy efficiency and an overall reduction in carbon emissions. Mits Air has received great responses to Mitsubishi Electric’s commercial VRF City Multi, the commercial MrSlim P-Series, the residential MrSlim M-Series and Zuba Central systems.

The benefits of Mitsubishi Electric’s commercial City Multi VRF 2-pipe system can be seen in the new headquarters of Enermodal Engineering Ltd. City Multi is a premium, eco-friendly multiple split, 2-pipe system that connects one condensing unit to multiple indoor units and can provide heating, cooling or both to any structure. It uses ozone friendly R-410A refrigerant and is one of few heat pumps that can provide room comfort when outdoor temperatures drop to -25°C and beyond.

Enermodal, one of Canada’s largest green building consulting firms, sought LEED certification in its construction of its new 22,000-square-foot headquarters in Kitchener, Ontario. Enermodal chose the City Multi VRF which used only 70 kWh/m² over a 36-month review period (the Canadian average is 375 kWh/m²). The building has been awarded three LEED platinum certifications and consumes only about 15% of the energy consumption of a typical Canadian office building.

In another example, MrSlim™ M-Series ducted SEZ/SUZ split system was used in 2013 to retrofit downtown Toronto’s Cathedral Court Co-op. The MrSlim™ M-Series is a single or multiple split system that provides cooling when outdoor temperatures are as low as -10°C and heating when outdoor temperatures are as low as -25°C. This solution was chosen given its energy sustainability, lower carbon footprint, ease of maintenance and overall reliability and longevity. This solution has performed exceptionally well, with no problems or failures of equipment during Toronto’s 2014 winter season with temperatures of -31°C and beyond.

Mitsubishi Electric’s Zuba Central is a premium electric air to air heat pump that provides both heating and cooling. It has a high efficiency ECM motor, uses ozone friendly R410A refrigerant and produces no CFCs or HCFSs with no Ozone Depletion Potential. It is an Energy Star qualified heat pump with S.E.E.R. ratings up to 15.0 S.E.E.R. in cooling mode and HSPF ratings of 9.4 in heating mode. Zuba Central was the subject of a performance assessment at the Kortright Centre for Conservation in Maple, Ontario, in conjunction with the Sustainable Technologies Evaluation Program (STEP) from Ryerson University. It was found to be a more cost-effective alternative to geothermal systems and a more energy-efficient alternative to conventional HVAC systems, exceeding EnerGuide ratings across all measure indicators.

Aside from its long standing representation of Mitsubishi Electric products, Mits Air’s new alliance with Aermec fits perfectly with Mits Air’s high-end, energy efficient product lines.

Aermec demonstrates its commitment to the environment by continually meeting global energy savings and environment protection challenges in the development of their new technologies.

All Aermec products available for North American applications use R410A, an ozone friendly refrigerant with a high thermodynamic efficiency that leads to, together with the use of multiscroll technology, a reduction in CO2 emissions. The savings obtained when using Aermec for cooling in the summer, heating in the winter, providing domestic hot water, and recovering energy year-round, result in a 35% reduction in CO2 emissions compared to traditional R407C heat pumps and standard chiller and boiler systems.

As for materials used for the piping systems, Vesbo PP-R pipes and fittings incorporate a fusion weld process to cover a wide range of applications. Known as an “all one piece” of material, Vesbo products are manufactured from polypropylene random copolymer resins, known as PP Type 3 raw material. With an inherent layer of fibreglass incorporated in the pipe, typical insulation thicknesses can be greatly reduced as well.

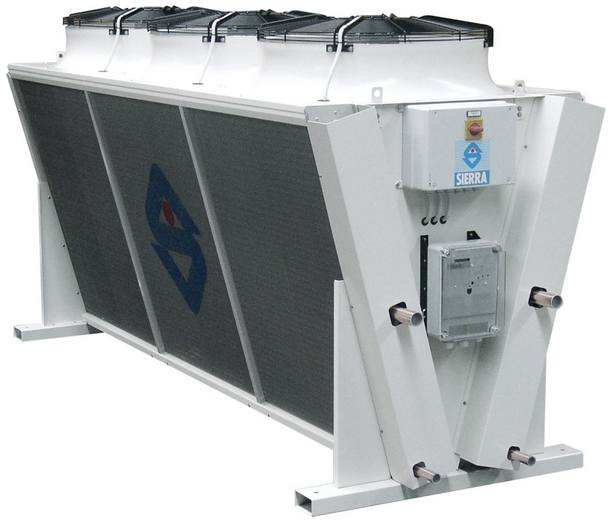

Two of Aermec’s products that have attracted much attention in North America are the NRL air to water heat pumps and chillers (13-260 tons) and the NRP multipurpose air cooled units with axial fans. The NRL units have been used in several successful case studies, including British Columbia’s Surrey Memorial Hospital, where three NRL3600 chillers with total heat recovery were installed to provide 750 tons of cooling and free/recovered heating all year round – thereby reducing energy and environmental costs.

Aermec’s NRP is North America’s only simultaneous heating and cooling unit with full heat recovery. With TER or COPs of up to 9, one can obtain great energy efficiencies while benefiting from any amount of heating or cooling, whenever it is required. Among other applications, the NRP is being used in the BC Hydro Northern Regional Operations building in Prince George, British Columbia, where two multipurpose heat pumps NRP700E4R2 with COPs twice as high as traditional chiller/heat pump systems will be used to provide unmatched energy-efficient and environmentally friendly heating and cooling.

In 2014, moving ahead, the goal for Mits Air is to increase its market share by enhancing its product offerings, building its employee team, and obtaining greater exposure to both Canadian and U.S. markets through trade shows, e-communications and the use of webinars and other related e-products.

At the heart of it all, one constant remains: for difficult heating, ventilation or air conditioning (HVAC) jobs, the team at Mits Airconditioning Inc. will not only embrace the challenge, but will design an efficient solution that meets the needs of each individual client.

Web

mitsair.com

aermec.ca

aermec.us

Archetype Sustainable House: Celebrating Five Years of Demonstration and Research

By Tracy Hanes and Tim Van Seters

When it was constructed at the Kortright Conservation Centre in 2009, the Archetype Sustainable House (ASH) was intended to be a state-of-the-art “green” abode that would demonstrate viable, sustainable housing.

The goal of the ASH, built by the Toronto Region Conservation Authority (TRCA) and the Building Industry and Land Development Association (BILD), was to educate the public, builders, and housing industry professionals about leading-edge building practices and products and how they could be used to create sustainable homes and communities. The house has achieved some of those objectives, as well as providing invaluable research through energy and water monitoring by universities and colleges in partnership with TRCA’s Sustainable Technologies Evaluation Program (STEP).

The ASH, actually two semi-detached units at the Living City Campus at Kortright, is one of the most efficient renewable energy houses in North America. One showcases the best green building practices available, while the other highlights up-and-coming technologies.

Features include solar photovoltaic roof panels, a wind turbine, in-floor radiant heating, heat and energy recovery ventilators, low-VOC finishes, waste-water recycling and drain water heat recovery units.

“Not only were these two semi-detached houses to be a showcase of the best in green building technologies, but we also wanted to learn what works best and how they can be configured to optimize costs and energy performance,” says Larry Brydon, who was on BILD’s board in 2007 when the decision was made to construct the twin houses, and served as BILD’s project manager.

In 2005, a national design competition, sponsored by TRCA (which operates Kortright) and run by the Design Exchange, called for a four-bedroom home designed for mass production, that had innovative waste-water treatment and would meet LEED Gold (Leadership in Energy and Environmental Design) and Energy Star standards. The design had to be flexible to allow for intensification.

The winning design, Building Blocks, was created by a Toronto team that included Anne Stevens (FORT Architect Inc.), Clelia Lori (Iori Architects) and Terrell Wong (Stone’s Throw Design). They designed modules that could be combined to create singles, semis or townhouses and to accommodate varying family size. They submitted the idea for two semis, 1,800 and 2,300 square feet.

The design allowed for factory manufacture and site assembly or for conventional on-site framing. In 2010, the house was awarded LEED Platinum status.

Half a decade later, the TRCA and BILD are looking at what has been learned, and how that information can help improve sustainability in the residential construction sector.

This has been facilitated by instrumenting the house as a laboratory with over 300 sensors that feed into a state-of-the-art data acquisition system. Many technologies have been installed so they can be easily replaced or reconfigured as newer, more advanced options become available.

Data collected for analysis includes: air temperature, relative humidity, and volumetric flow rate; water temperature and flow rate; natural gas consumption; solar radiation; and power consumption of individual components. It is among the most comprehensive residential energy monitoring projects worldwide.

The most important lesson is not so much about the houses, but how the systems integrate, according to David Nixon, monitoring coordinator for STEP.

“Often an electrical or mechanical device will have a performance rating that gives the buyer some sense of how efficient the device is and the savings that can be achieved by using it,” explains Nixon. “But when these are installed as part of a system, the performance can change significantly.”

One example is the heat recovery ventilator, installed to ensure an adequate supply of fresh air in the well-insulated house. As a stand-alone system, the HRV is meant to minimize heat loss, but when coupled with the air handling unit, the fan was forced to run at higher than optimal speeds, resulting in wasted energy.

“Balancing the system at low fan speed would provide better fresh air distribution at lower energy cost,” says Nixon. “There is a simple solution, but experimental research is needed to standardize an approach that will work best in a variety of different contexts.”

Dr. Alan Fung from Ryerson University’s Department of Mechanical and Industrial Engineering worked with two of his students to develop the matrix for selecting technologies to be installed in the house and has supervised more than ten graduate students who conducted research there.

“What really sticks out in my mind is the research we did on the variable capacity air source heat pump,” says Fung. “We didn’t expect to see such high performance during the winter, especially at low temperatures. The heat pump operated for most of the heating season on part load, at a performance level that was well above the rated capacity.”

Public tours and education programs target homeowners, students and professionals/trades in the building industry.

Alex Waters, senior manager of the Living City Campus, says that over 10,000 students, 2,000 professionals, and 2,500 homeowners have toured the ASH and it has been used for consumer workshops such as eco-home renovations, efficient heating systems and DIY solar. “The response has been very positive,” says Waters. “People like that they can see the latest in green building design and get unbiased advice as to what works and doesn’t. Visitors love the open concept and the amount of space these small footprint houses have. The most surprising comments concern the renovation-ready attic and the one switch which turns off all the lights in the house.”

The success of the ASH and other technology demonstrations contributed to the British Research Establishment’s (BRE) decision last year to select the campus to be Canada’s Innovation Park, part of the BRE Innovation Parks Network across the globe. This will result in the construction of up to eight more low rise buildings next to the ASH that showcase innovative construction and low carbon technologies, and demonstrate integrated designs that are practical and affordable.

If you are a fan of sustainable approaches and design, that really will be something to see.

For more information about the ASH and five year anniversary event in June, visit www.livingcitycampus.com

Tracy Hanes is a freelance writer. Tim Van Seters manages the TRCA’s Sustainable Technologies Evaluation Program

Vincent Callebaut Architectures: THE FLAVOURS ORCHARD

CONSTRUCTION OF 45 PLUS-ENERGY (BEPOS) VILLAS IN A SMART GRID

KUNMING 2014, YUNNAN PROVINCE, SOUTHWEST CHINA

1. CHINA’S ECO-HIGH-TECH CITIES : TOWARDS AN ENERGY  EFFICIENT COMMUNITY IN KUNMING

EFFICIENT COMMUNITY IN KUNMING

Stepping out of your plus-energy house regulating the light and the temperature cleverly and automatically according to the sun’s path. Catch the vital energies of the nature by training ourselves Tai Chi Chuan or Qi Gong under a snow of cherry tree petals. Cultivate together with our neighbors the community vegetable garden. Harvest the organic vegetables for the family dinner. Wander between the marshes of rainwater harvesting and the recycling lagoons where the sky of koï carps is covered of lotus flowers. Swim in a naturally filtered swimming-pool. Admire the elegant and nagging axial wind turbines.

Listen the laughter of children of the eco-district who share with their grandparents the games of Mahjong, Go and Cuju in the wild field. Recycle our organic waste in compost wells producing natural fertilizer. Sort out the other waste via a silent and underground pneumatic collection system. Go to work by electric bicycle or driverless car (Electric Networked-Vehicle), both recharged directly by the photovoltaic roof of the house. Follow the road whose sensory LED lights match according to sounds and movements of the city-dwellers.

This is the Eco-High-Tech atmosphere of the “Flavours Orchard” project. It’s a pioneer project that fights for the conception of eco-responsible lifestyles along the Daguan river connecting the “Emerald”, the green lake of the city centre of Kunning, to the magnificent Dianchi Lake in the South. Capital of the Yunnan province, the city is located at 1894 meters high and benefits from a temperate climate all the year that gives to it the charming name of « The City of Eternal Spring ».

The site of several hectares is an old industrial wasteland devoted to be restored in a new eco-district whose exemplarity in terms of sustainable innovations is supposed to be reproducible everywhere in China. The leitmotiv is to produce more energy and biodiversity than we consume by recycling at the same time our waste in reusable natural resources endlessly towards a post-nuclear, post-fossil and zero carbon emission city. Through the creation of such projects, China is recovering its delay on the ecological debt reimbursement and tries to slow down the massive rural exodus it suffers by the creation of new urban prototypes mixing all the advantages of the city and the countryside.

2. 45 PLUS-ENERGY (BEPOS) VILLAS PLANTED IN THE SMART GRID OF A COMMUNITY ORCHARD

The building sector is a primary energy consumer particularly in China (40% of total consumed energy) in front of the transports (30%) and the industry (30%). It is responsible for more than 40% of total emissions of CO2. It’s obvious that the energy savings are thus the major economic and ecological challenge for this sector. Whereas the prices of the fuel and the non-renewable energy increase unavoidably, the objective is to divide by 10 the consumption of this construction sector for an equivalent service within the next ten years.

In this perspective, the concept of this new « Flavours Orchard » eco-district is to build 45 Plus-Energy Villas in a huge community orchard/food garden integrating a Smart Grid self-managed by the gardener-inhabitants and the participants of the project.

In the heart of this nourishing landscape, the goal is to associate a state-of-the-art for smart building automation systems and information integrated in each villa (leading to cost reduction and Increased functionality) with an intelligent energy network in order to redistribute the produced excess (electric, calorific, food) towards the nearest needs so as to prevent from the loss in lines or related to the storage systems. In addition to the fuel cells, the electric vehicles are also used as buffer storage of electricity excess produced by the solar roofs assuring thus the daily travels of the inhabitants for free.

The objective is also to repatriate the production of the organic agriculture in the heart of the city, center of its consumption. This bio-geographical integration of the master plan respects the natural qualities of the site and maintains the continuity of the endemic ecosystems (trees, hedges, streams, floras and fauna are preserved). Flavours Orchard is a genuine garden sharing its energies designed and cultivated collectively. Ideas are here more shared than the ground, the sun or the wind because it deals not only with producing what to eat, lighten and air conditions but also to meet on a common ground of ecological experimentations and collective projects. It’s an urban landscape open to everybody without fence between the villas, in favor of the neighborhood relationships and the intercultural and intergenerational social links. It’s an educational tool about the environment respect thanks to its ecological master plan, its organic agriculture technics, its smart home automation strategies and its integration of renewable energies.

The private garages for electric cars and the technical rooms for home automation are located underground. This basement distributes each villa under the central path to liberate completely the orchard dedicated only to pedestrians, cyclists or electric driverless cars.

The future families of these Plus-Energy villas will be able to live and work comfortably in their villa reinventing new eco-responsible lifestyles maximizing the normal living standards.

The 45 Plus-Energy Villas produce more energy from renewable energy sources, over the course of a year, than they consume from external sources. This is achieved by using large North and South facing window areas to allow sunlight to penetrate the structure, by reducing the need for energy use from air cooling units and light bulbs with triple-glazed windows, and by the addition of heavy insulation that means the structure is already warm in the evening and therefore needs less heating.

These passive buildings (BEPAS) that capture heat during the day in order to reduce the need to generate heat over night, exceed their energy needs through renewable energy production by the integration of solar photovoltaic and solar thermal panels, geothermal heat exchangers, and combined heat and power units (CHP). All grey water is recycled in lagoons for agricultural irrigation and toilet flushing. All waste water will be sent to bio-reactor facades (with panels filled with algae) for anaerobic digestion and the methane emitted during the digestion process will be used to produce energy and to cool the interiors.

The construction of positive energy constitutes a high technological and conceptual rupture. These villas are thermally insulated without discontinuity and without thermal bridges. They are airtight, present controlled ventilation and are also equipped with economical domestic appliances of A+++ class. They generalize the LED lighting with automatic detection of presence and needs. They have a total consumption of primary energy (heating, sanitary hot water, lighting, all appliances) estimated at less than 50 kWh/m2/year for an average production that can reach 100 kWh/m2/year via the sun or wind. According to the usage of inhabitants, the consumption of primary energy could even decrease under 35 kWh/m2/year.

The 45 villas building with a wood/steel structure are divided into three architectural typologies forming thus 3 eco-districts having their own identity:

2.1. THE “MOBIÜS” VILLA (15 units)

The Mobius Villa is organized around an endless ribbon drawing the symbol of infinity around two patios, one aquatic and the other planted. This ribbon with primary steel structure and secondary wood frame is built from the repetition of one trapezoidal module repeated 24 times in the space. This module, opened at 30 degrees forms thus a pedestrian sloping path of 720 degrees along its double revolution. It contains all the bedrooms, the bathrooms, the offices, the libraries and the game rooms. It is covered by a green roof, true suspended vegetable garden with high thermal inertia and with a zenithal photovoltaic glass roof. The curved geometry forms a snake in sustentation on top of a façade in “8” with supporting frames. Louvered shutters in translucent glass pivot automatically along this glass facade to regulate the solar inputs during the day.

The panoramic ground floor aims at immersing the diurnal life spaces in the heart of a clearing coiled in the orchard. The living room, the kitchens and reception rooms are located around the central vertical axis of the project. Actually at the intersection of the double loop, the vertical circulations distribute the 4 inhabited levels and the garden roof.

2.2. THE “MOUNTAIN” VILLA (15 units)

The Mountain Villa opens out at 180 degrees such as a huge Chinese fan built from east to west to ideally follow the sun’s path. It’s a double-skin architecture presenting a south facade very glazed and a very opaque north façade in wood presenting 20% of perforation. The 22 arches are linked together by cables. They are closed by solarized photovoltaic glass panels. Panels filled with algae are also integrated to the conception in the 7 central arches to produce bio-hydrogen. The second exterior skin develops a glued laminated timber frame and works as a huge windscreen shaped in wood lace. This trellis enables to assure the intimacy of the inhabitants and to regulate the inputs of heat by subduing the solar rays from east to west.

In the center of the villa, an atrium full of light raises on 4 levels. A spiral staircase coils around a panoramic glazed elevator to distribute all the night and relaxation spaces. The living rooms and reception spaces are opened towards the landscape by a big arch going through the North and South facades.

2.3. THE “SHELL” VILLA (15 units)

The Shell Villa liberates itself from the ground on its 6 stainless steel pillars to stretch towards the sky and to make its axial wind turbine higher than the top of the fruit trees. A circular deck takes the loads of a glued laminated timber carpentry that is plaited in diamonds such as a conical Chinese hat. It’s a cocoon villa drawn in double curves and organized around three patios in spiral that fit closely the membranes of the twisted wood beams.

These patios are isolated by the glass façades whereas three stainless steel petals put on insulating cushions coat the structure from outside. This radiant wood structure is divided into 36 standardized beams that are spaced out from each other by 10 degrees from their center. Thus, from the life spaces we obtain panoramic views on the whole orchard whereas an elevator goes through all the levels to the top of the mast of the axial wind turbine.

These three typologies of Plus-Energy Villas set up in the clearings of the great community orchard are the symbol that it is possible to invent new contemporary models of eco-responsible housing mixing the economical evolution in China and the worldwide respect of the environment. The precursory inhabitants are linked together by their citizen commitment for a new ecological ideal that is energetically efficient, collective and sustainable.

Through Architecture, the social life between city and countryside is first of all reinvented!

© Vincent Callebaut Architect