World’s first fully functional 3D printed office building

Located at the foot of Emirates Towers, the Office of the Future is the world’s first fully functional and permanently occupied ‘3D printed’ building. The 253 sqm building acts as the home for the Dubai Future Foundation and as an exhibition space and incubator for future emerging technologies in the emirate.

The “Office of the Future” is the first 3D-printed building of its kind. A 3D-printer 20 feet high x 120 feet long x 40 feet wide was used to print the building. The printer features an automated robotic arm to implement printing process. The entire structure was printed using a giant cement printer using an additive manufacturing technique, then assembled on site. Printing took 17 days and installed in two days. Subsequent work on the building services, interiors and landscape took three months.

The labour involved in the printing process included one technician to monitor the function of the printer, a team of seven to install the building components on site, 10 electricians and specialists to take care of MEP. Labour cost thus, was cut by more than 50% compared to conventional buildings of similar size. Other projects have tested various elements of 3D printing before, but the Office is the first real building to be built at scale, with full services, that people can use on a daily basis.

The initiative comes as part of Dubai’s 3-D Printing Strategy, which was launched on April 27, 2016 and focuses on the development of 3D printing to improve people’s lives. It will tackle three sectors: real estate and construction, medical, and consumer, and commits the Emirates to the use of 3D printing in 25% of its buildings by 2030.

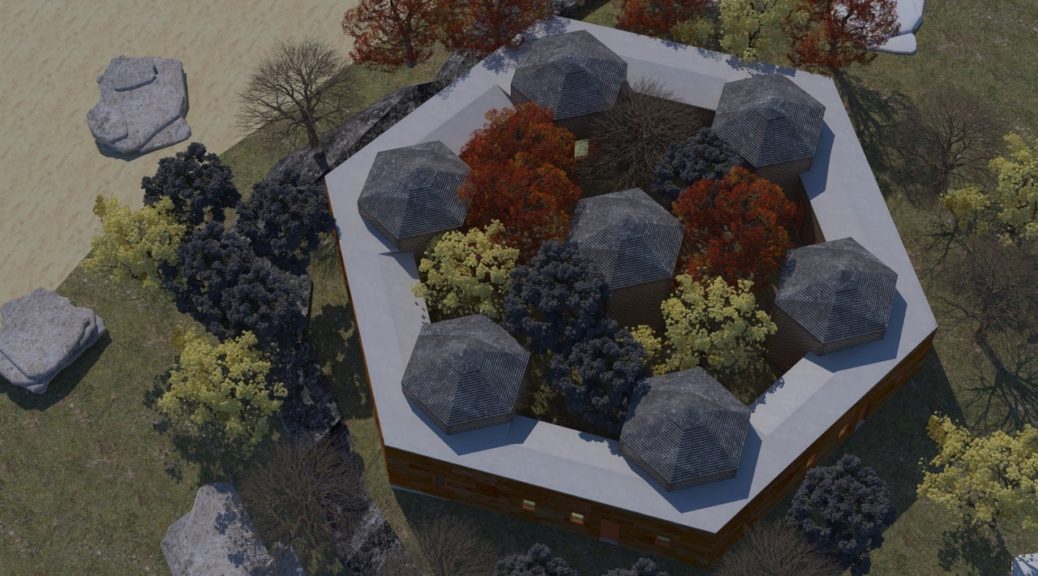

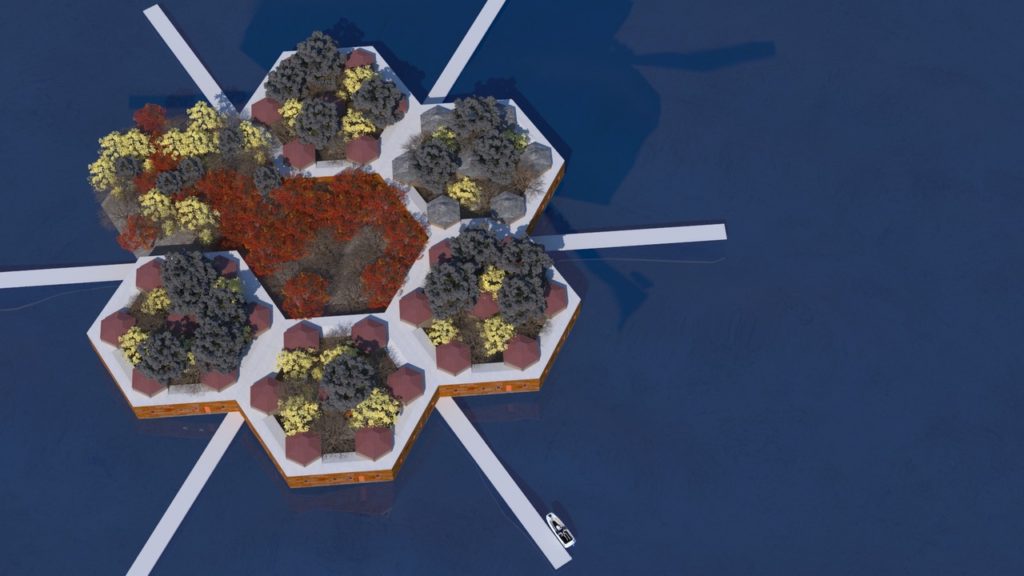

The Office radiates around a tree shaded cafe courtyard. It provides a partnership lounge & gallery for exhibitions, events and workshops, a flexible space for team brainstorming and design work and private meeting rooms. A series of openings throughout the project bring natural daylight deep into the space while allowing occupants to remain connected to the outside environment.

The building envelope design is inspired by natural coral. Coral has been used for generations as a traditional building material in the UAE. It is easy to handle and to work, has excellent thermal properties and provides a beautiful texture to the building surfaces. Killa Design aimed to recreate this traditional beauty in a sustainable manner by 3D printing cladding elements with the beauty and complexity of coral. In this way, the project seeks to merge the age-old tradition of coral construction with the latest technologies and fabrication techniques.

The building is extremely energy efficient. It is oriented to maximize visibility and natural light, but to shade the inside through digitally sculpted overhangs above the windows. This minimizes direct solar heating and reduces the need for air conditioning and lighting. Further sustainability features include 100% LED lighting, responsive building systems, green landscaping, and low energy air conditioning and cooling. Wastage on site was minimized and thus helped reduce the environmental footprint of the project.

As part of a wider initiative to be involved in the most cutting edge and innovative projects, Killa Design made use of a super insulated cladding system with 800mm thick panels constructed using computer controlled manufacturing techniques to create the unique form of the building and complex geometry of the building envelope,

As part of a wider initiative to be involved in the most cutting edge and innovative projects, Killa Design made use of a super insulated cladding system with 800mm thick panels constructed using computer controlled manufacturing techniques to create the unique form of the building and complex geometry of the building envelope,

” The progressive design of the office conveys a shift from the traditional form of work environments thus paving the way for stimulating innovation and communication within teams.”

– Ben Piper, partner at Killa Design

Web: www.killadesign.com

shire Homes, targeting intricate construction for every home.

shire Homes, targeting intricate construction for every home.

The exhibition 2017 is entitled “This-CONNECTION – sharing a future of public space”, it features art, architecture, urban planning, design interpreting the future of the cities.

The exhibition 2017 is entitled “This-CONNECTION – sharing a future of public space”, it features art, architecture, urban planning, design interpreting the future of the cities.