Accolades for Arista Homes for its green building practices

NATURAL RESOURCES CANADA ENERGYSTAR NEW HOMEBUILDER OF THE YEAR

Being true to its company philosophy is reaping ongoing benefits for Arista Homes Limited.

Founded more than 20 years ago by Michael DeGasperis, the Vaughan-based

Homebuilder of more than 9,000 quality homes across the GTA and Southern Ontario has long been recognized as an industry leader in both innovation and technical excellence – and that’s a key part of its Mission Statement. “While building upon a Life-Friendly TM corporate philosophy, we will encourage the development of our exceptional people to build exceptional homes and communities and deliver a product to our clients that we would be proud to own.” The entire Arista Homes team is motivated by this Mission Statement. Arista’s dedication and commitment to always improving and building the best possible home, alongside being environmentally conscientious, has not gone unnoticed. In fact, Arista Homes was recently recognized as the 2015 Natural Resources Canada (NRCan) Energy Star New Homebuilder of the Year. Receiving this prestigious National Award is certainly a proud accomplishment!

“We take great pride in receiving this nationally recognized award,” says Michael DeGasperis, Arista’s President and C.E.O. “We remain committed to collaborating with suppliers, trades and each of our dedicated employees to ensure we continue building a product for our valued clients that we would all be proud to own ourselves.”

For more than two decades, Arista Homes has embraced green building initiatives and remains determined and dedicated to doing so in the years ahead. The continued implementation of green initiatives, panelized construction practices, recycling programs, and improved construction processes all contribute to a better-built home, which ultimately leads to a more environmentally friendly home and an even more satisfied homebuyer.

The National Energy Star award provides significant acknowledgment of Arista’s efforts and is a direct result of the company promoting the Energy Star brand along with other worthy green building initiatives. Most importantly, there’s no doubt that Arista has embraced a corporate philosophy that is predicated upon building the best possible homes and a strong desire to be environmentally conscious.

“I am proud to live and work in one of the world’s greatest countries,” says DeGasperis. “I take great pride in being entrusted by our homeowners to, in essence, make their dreams come true. This is a significant responsibility that I do not take lightly. Not only

does it motivate me daily, but I derive great satisfaction in future generations aspiring to make an Arista home their own.”

Arista Homes is not satisfied in simply meeting today’s homebuyer expectations; rather the Arista mandate is to exceed these expectations whenever possible.

The utilization of panelized wood construction practices has become the norm in all Arista communities. Arista has embraced the technologies and industry-leading advancements provided by forward thinking companies such as Panelized Building Solutions (PBS) and Tamarack. These companies are at the forefront of providing homebuilders with engineered, factory-built and locally co-ordinated wood panelized products. The expertise provided by their respective design teams has allowed Arista to implement effective on-site strategies that have had a significant impact in not only reducing the carbon footprint left behind, but also a positive effect on Arista’s ability to build a better home.

With several panelized Arista communities now complete, Arista has found that the overall cost effectiveness associated with panelized wood construction along with the many immediate benefits associated with this superior construction method, both immediate and long-term, far outweigh those of conventional house construction.

The immediate benefits of panelization are undeniable and can be measured to include the following:

Built the right way, the same way every time.

Save time – 37% faster than conventional stick frame construction = greater economies and efficiencies

Produces a superior quality finished product.

Cleaner and safer workplace, virtually no waste material

Reduces required on-site labour force required for clean-up.

Reduced WSIB costs.

A near 50% savings on typical waste-bin costs.

Virtually eliminates equipment required to clean up sites.

Cost certainty – as one all-inclusive price is provided.

Panels are built in a controlled heated environment to exact dimensions.

Fixed delivery dates.

Less weather related delays – helps you stay on schedule and on budget.

Floor and wall assembly systems are tailored to individual builder/client needs and specifications.

Installed with cranes, thus significantly reducing on-site labour.

Saves space on site for material staging areas.

Arista’s clients have been quick to recognize this effort. Arista’s V.P of Sales and Marketing, Franco Crispino states: “This exceptional green-friendly initiative can only be described as a huge success.”

Beyond panelized construction, Arista continues to implement many other technologies and advancements into each of their homes. Their current mandate, is to ensure that all new Arista communities are Energy Star-compliant and to build upon their many successes in the green building environment.

Each Arista Energy Star-built home incorporates individual energy-efficient home components and building materials. Such practices effectively contribute to an approximately 25% more energy efficient home when compared to the current building code – much to the delight of each Arista homebuyer. Each home not only exceeds the current standards but ultimately saves the homeowners money as well. In addition, Arista also adheres to neighbourhood friendly on-site environmental protection measures by providing homeowners an introduction to solar-ready conduits and the integration of future energy-saving technologies and water conservation initiatives (e.g. low-flow faucets, high-efficiency flush toilets). Furthermore, improved indoor air quality is achieved with the introduction of environmentally-friendly building materials as well as Heat Recovery Ventilation Systems (HRV’s) as well as several other construction details that are geared towards a more air-tight home.

As far as community development goes, neighbourhood street patterns and designs are given careful consideration in order to create pedestrian-friendly sidewalks and neighbourhood –friendly green spaces. Wherever possible, Arista promotes transit hubs, easy access to public spaces and recreational facilities – anything that can limit the

use of automobiles and make life easier and more satisfying for homeowners. This also includes Live/Work communities. To top it all off, water conservation mandates and policies, proper storm water management, tree preservation, rain barrels and homeowner education are commonplace in many Arista Homes community. Arista cares and it shows.

For more than 20 years Arista has strived to be the industry leader and to assist the building community whenever possible. Part of that means being committed to providing leadership, input and time required to assist in educating clients, trade partners, fellow builders, policy makers and to ensure that the consumer gets the best home possible. Moreover, Arista aims to do this in a responsible manner that will provide both immediate benefits today and ultimately for future generations as well.

Collectively, the Arista Homes initiatives have all contributed significantly to not only building a better home, but also has enhanced the company’s ability to rise above its competition.

“It’s been an incredible 20 plus years,” says Michael DeGasperis. “We have the privilege of working in the most exciting of industries. The rewards can be satisfying, but there is no room for complacency. As this industry evolves, and the market conditions shift, our homebuyers’ needs and wants change. Therefore, we need to adapt quickly and lead by example – it is the only option.” “What this means,” says DeGasperis, “is that the Arista mandate is to be a leader and not a follower – always staying ahead of the crowd.”

Web / aristahomes.com

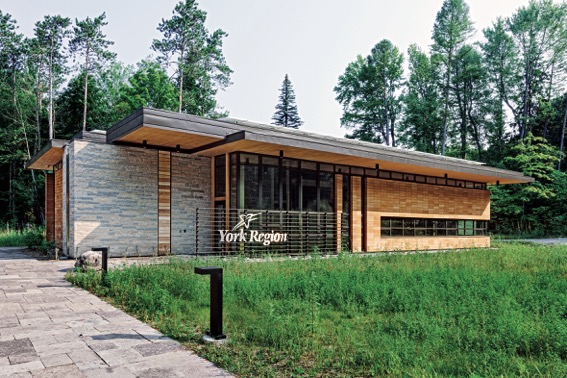

‘For Arista Homes’ new ‘Impressions of Kleinburg’ community, a designated Energy Star room was created to educate prospective buyers. Actual wall cross-sections depicting an Arista-built Energy Star wall system versus a typical Ontario Building Code wall system is on display, as is an HRV system, high-efficiency furnace, drain pipe recovery system, Energy Star window and necessary teaching aids; all geared towards educating the public and promoting the immediate and long-term benefits of owning an Arista-built Energy Star home.