RODUCT OVERVIEW

Purpose of this product:

Bioreactor Façade – A dynamic façade system for the production of renewable energy using algal biomass and solar thermal heat. Building Integration:

The system is suitable for both new buildings and existing buildings, and for industrial, commercial,

existing buildings, and for industrial, commercial, residential and public buildings.

Features and benefits:

Full integration of low energy design for energy efficient buildings with a Passivhaus standard;

conversion of natural light to biomass and heat; local storage and use of solar thermal

energy; sustainable energy design – near to CO2 neutral; dynamic and adaptive shading, since

with the increasing intensity of solar radiation the transparency and the degree of total energy

transmission (g-value) decrease; living and dynamic user experience created by the emerging

air bubbles and the variations of colour of the SolarLeaf elements; also applicable as a primary

façade system with additional benefits in terms of high thermal and acoustic insulation.

SOLARLEAF – THE BIOREACTOR FAÇADE

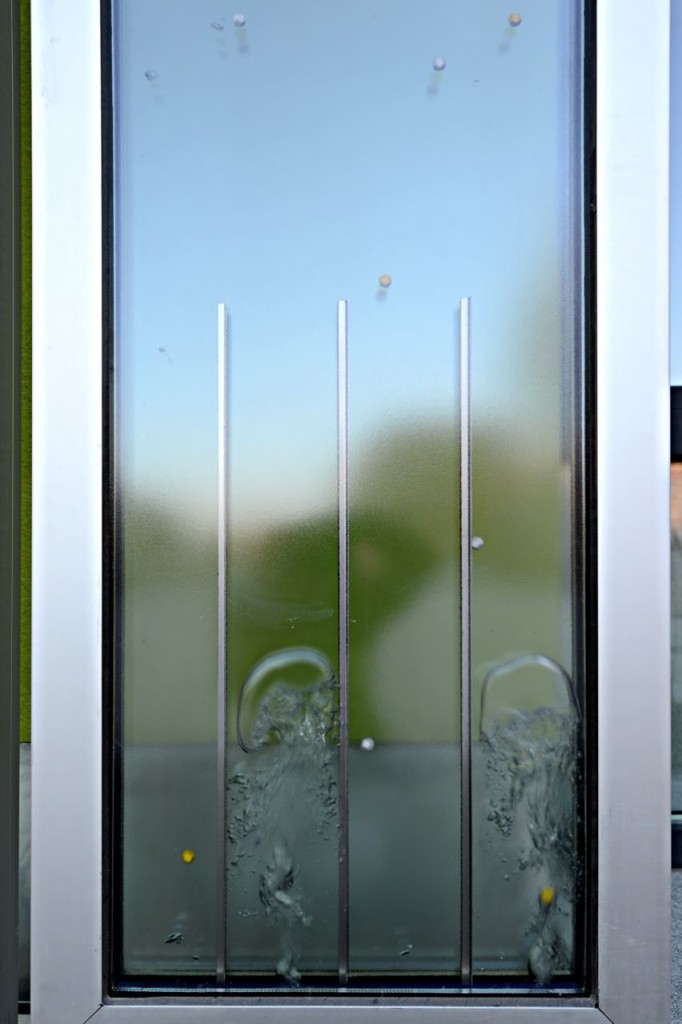

The vertical glass louvres are filled with water containing nutrients which conver

daylight and CO2 to algal biomass through the bio-chemical process of photosynthesis

at the same time the water is heated up by solar-thermal effects. The biomass and

heat generated by the façade elements are transported by a closed loop system to the

plant room, where both forms of energy are exchanged by a separator and a heat

exchanger respectively. The temperature levels of the heat generated can be increased by

of the heat generated can be increased by using a hot water pump for the supply of hot

water and for heating the building. Excess heat can be stored by use of a geothermal system.

The biomass has high energy content, and can therefore not only be used for generating

energy but also processed and used by the food and pharmaceutical industries.

To be able to benefit from the synergies of the system, a holistic and comprehensive

design approach is required right from the beginning.

From 2020 onwards, zero-energy houses will be obligatory in Germany and in some

other European countries. Every new building will need to produce the same amount of

will need to produce the same amount of energy as it consumes. In 2012, the energy

generated by photovoltaic systems and solar thermal systems in Germany provided 1.5%

thermal systems in Germany provided 1.5% of the total energy supply, while biomass

as a renewable energy source provided 8%.

The advantage of biomass compared to photovoltaic is that it is a form of solar energy

that can be easily stored and therefore doesn’t require expensive storage technologies

like batteries. The bioreactor façade is the first building integrated system to generate

biomass.

The conversion of light to heat is a well first building integrated system to generate

design. In contrast, the conversion of light to biomass is a biochemical process facilitated by

microscopically small algae, called microalgae.

Microalgae, like other higher level plants, use sunlight for the photosynthetic process and

this is linked to the process of conversion of much more efficient in the conversion of light

to biomass than higher-level plants, because they consist only of single cells, each of whic

is capable of photosynthesis. Microalgae can divide themselves up to two times a day and

thus increase their biomass by a factor of four.

Their biomass contains 23-27 kJ of energy per gram dry weight. This biomass can be used as

raw material for cosmetic and pharmaceutical products or is used for animal food or dietary

supplements. By varying the cell density in the culture medium the transparency can be

varied between 10 and 80%

HOW DOES SOLARLEAF WORK?

When used as a secondary façade the bioreactor elements form a rainscreen system

of the outer layer of a double-skin façade. The vertical elements have a size of 2.5m x 0.7m

and can span across a full storey if required. In addition they can rotate along its vertical axis

to track the position of the sun. When fully closed the SolarLeaf forms a continuous outer

skin providing a thermal buffer.

Each SolarLeaf element features a multiple glass assembly, designed to meet the latest

performance criteria of modern façade engineering. The two inner layers form an

18mm wide cavity with a capacity of 24 litres for the circulation of water and growth of

algae. For safety and thermal insulation the photobioreactor is clad on both sides with

laminated safety glass.

Compressed air is introduced to the bottom of each bioreactor at certain time

intervals. The gas emerges as large air bubbles and generates an upstream water flow and

turbulence to stimulate the intake of CO2 and light by the algae. At the same time, the

inner surfaces of the panels are washed by to the naked eye. The flat photobioreactors

are thus very efficient for algal growth and need minimal maintenance. All servicing pipes

for the inflow and outflow of the culture medium and the air are integrated into the

substructure of the SolarLeaf elements. At the BIQ pilot project in Hamburg 32 elements

are combined into a closed loop system and

connected to the plant room.

A central building management system controls all the processes necessary to

operate the bioreactor façade and to fully integrate it with the energy management

system of the building. This includes the control of the algal cell density and the

temperature in the culture medium.

The heat obtained from the façade has a temperature of about 40°C and is either

used directly to heat water or is stored in the ground by use of a geothermal system. The

system can be operated all year long.

The efficiency of the conversion of light to biomass is 10% and to heat 38%. For

comparison, photovoltaic systems have an efficiency of 12-15% and solar thermal

systems 60-65%.

So the bioreactor façade is competitive relative to these other technologies. In

addition, bioreactor façades remove CO2 from flue gas at quantities equivalent to th

build-up of biomass and thus reduce the CO2 emissions from buildings and help to improve

the overall CO2 balance.

“The “SolarLeaf ”

bioreactor façade is

pointing the way ahead

for the future of the

façade and low energy

engineering for Green

Buildings”

SOLARLEAF in OVERVIEW

A Solarleaf bioreactor façade:

– produces high value biomass (10% ECS*)

– produces solar thermal heat (38% ECS*)

– provides dynamic shading

– increases the thermal and acoustic

performance

Optimal conditions for building integration:

– Production of a constant flue gas or source

of carbon

– Production of heat throughout the year

– Ideal for south facing façades (>200 m²)

* ECS = energy conversion efficiency ratio, which indicates the percentage of the incoming light

energy converted to biomass or heat.